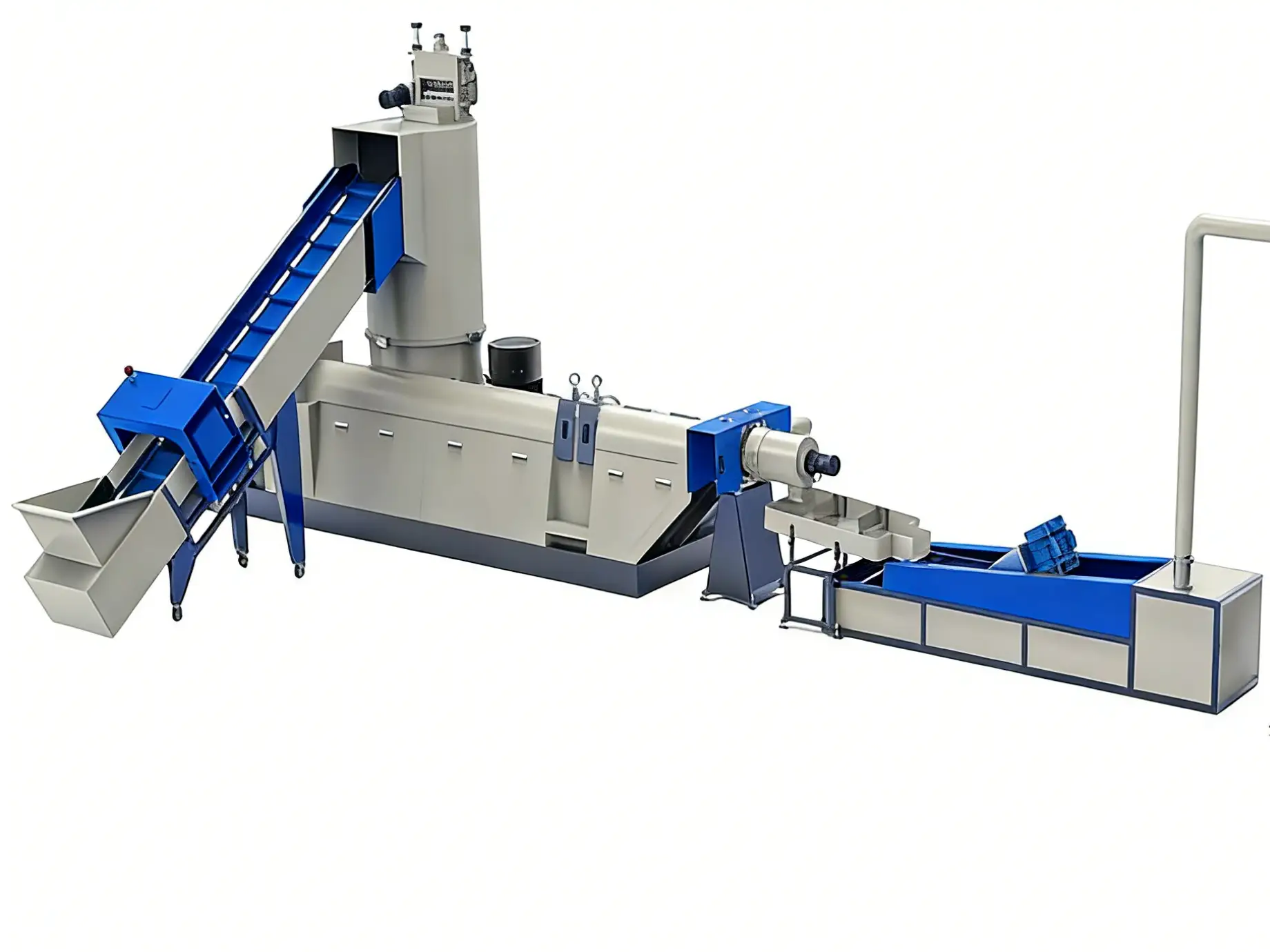

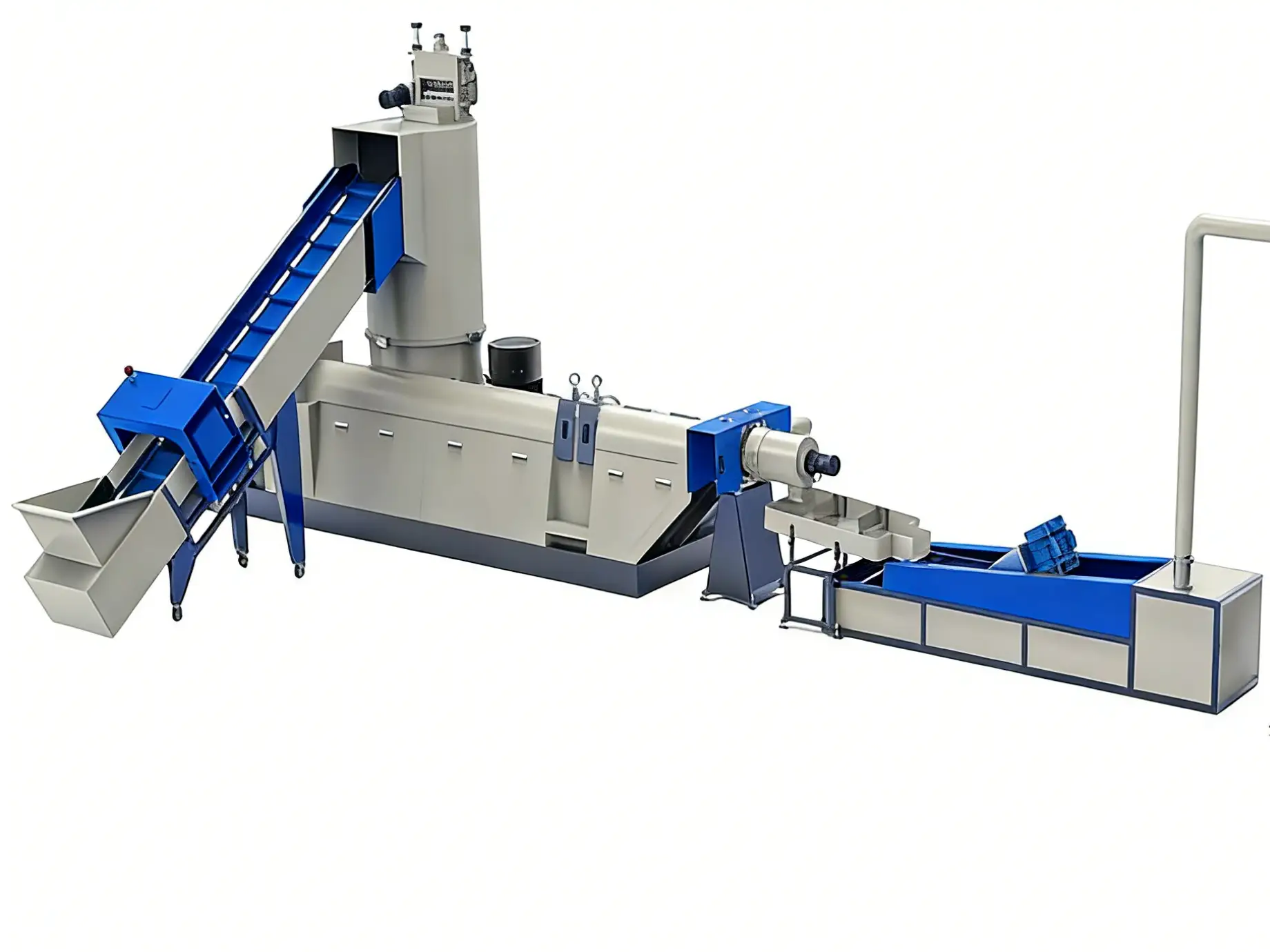

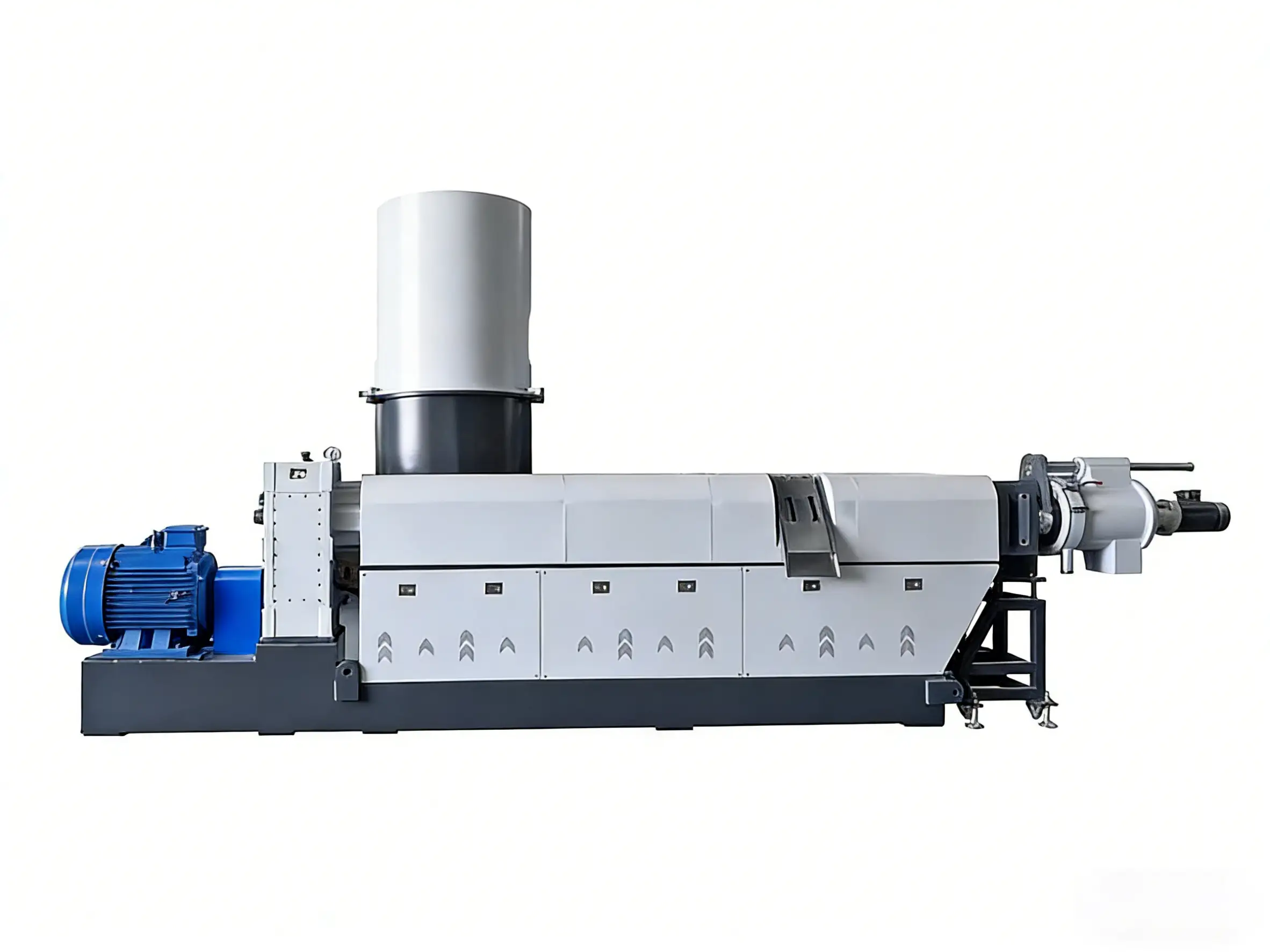

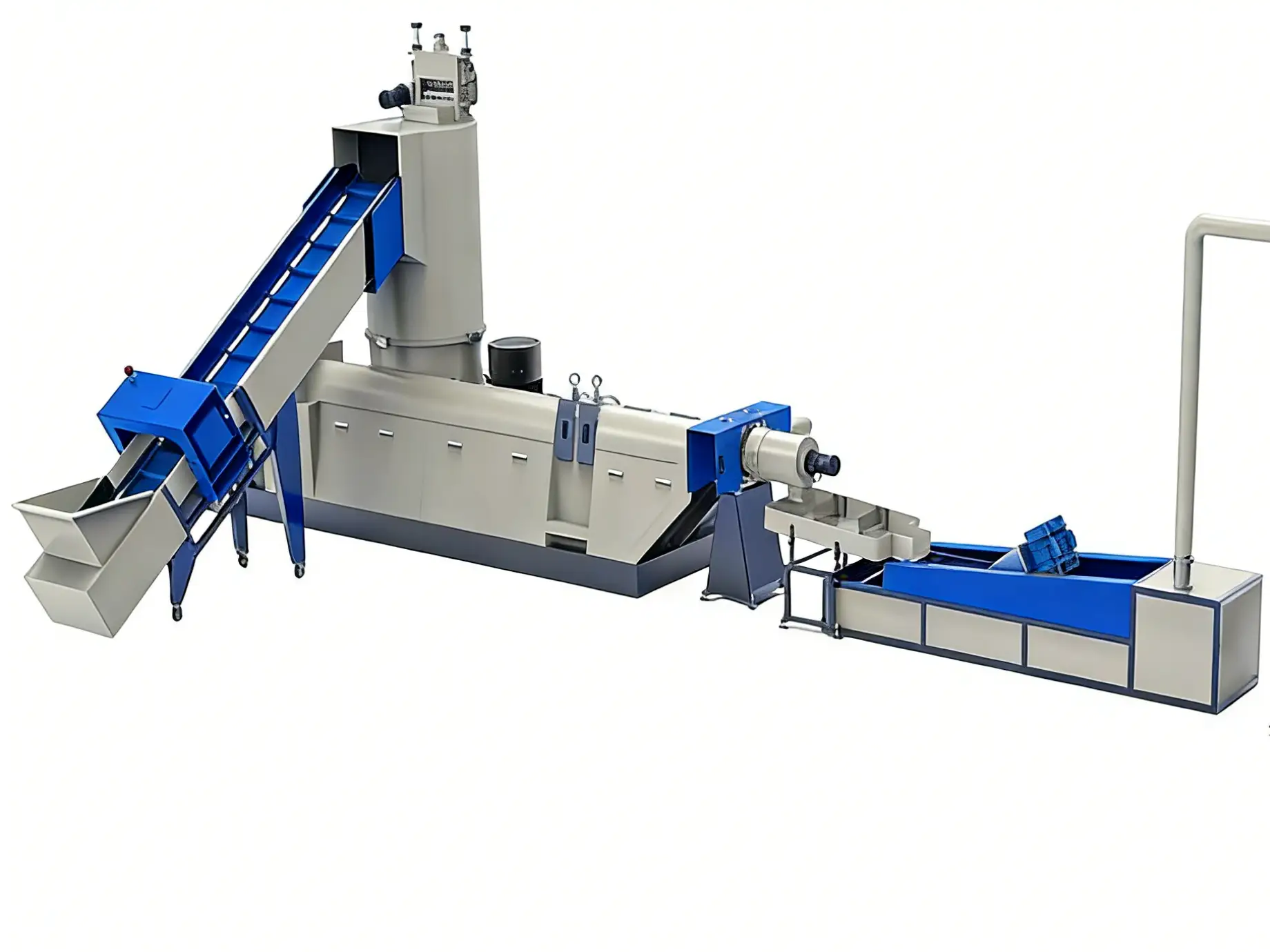

Rigid Plastic Double-Stage Pelletizing Line

Advanced pelletizing system for challenging mixed plastics (PVC, ABS, PS) or materials with fillers, impurities, or high moisture content. Two-stage extrusion ensures thorough melting and homogenization for stable pellet output.

Materials Available for Processing

Mixed Plastics

Mixed Plastics PVC / ABS / PS

PVC / ABS / PS Filler Materials

Filler Materials Regranulates

RegranulatesParameter Overview

| Model | Max. Output (kg/h) | Main Motor (kW) | Screw L/D | Pelletizing Type | Voltage |

|---|---|---|---|---|---|

| RPD-80 | 150–300 | 75 | 36–42 | Water Ring | 380V 50Hz |

| RPD-100 | 300–500 | 110 | 36–42 | Water Ring | 380V 50Hz |

| RPD-120 | 500–800 | 160 | 36–42 | Water Ring | 380V 50Hz |

| RPD-140 | 800–1200 | 200 | 36–42 | Water Ring | 380V 50Hz |

* Specifications may vary based on raw material condition and customer requirements. Project-based configuration available.

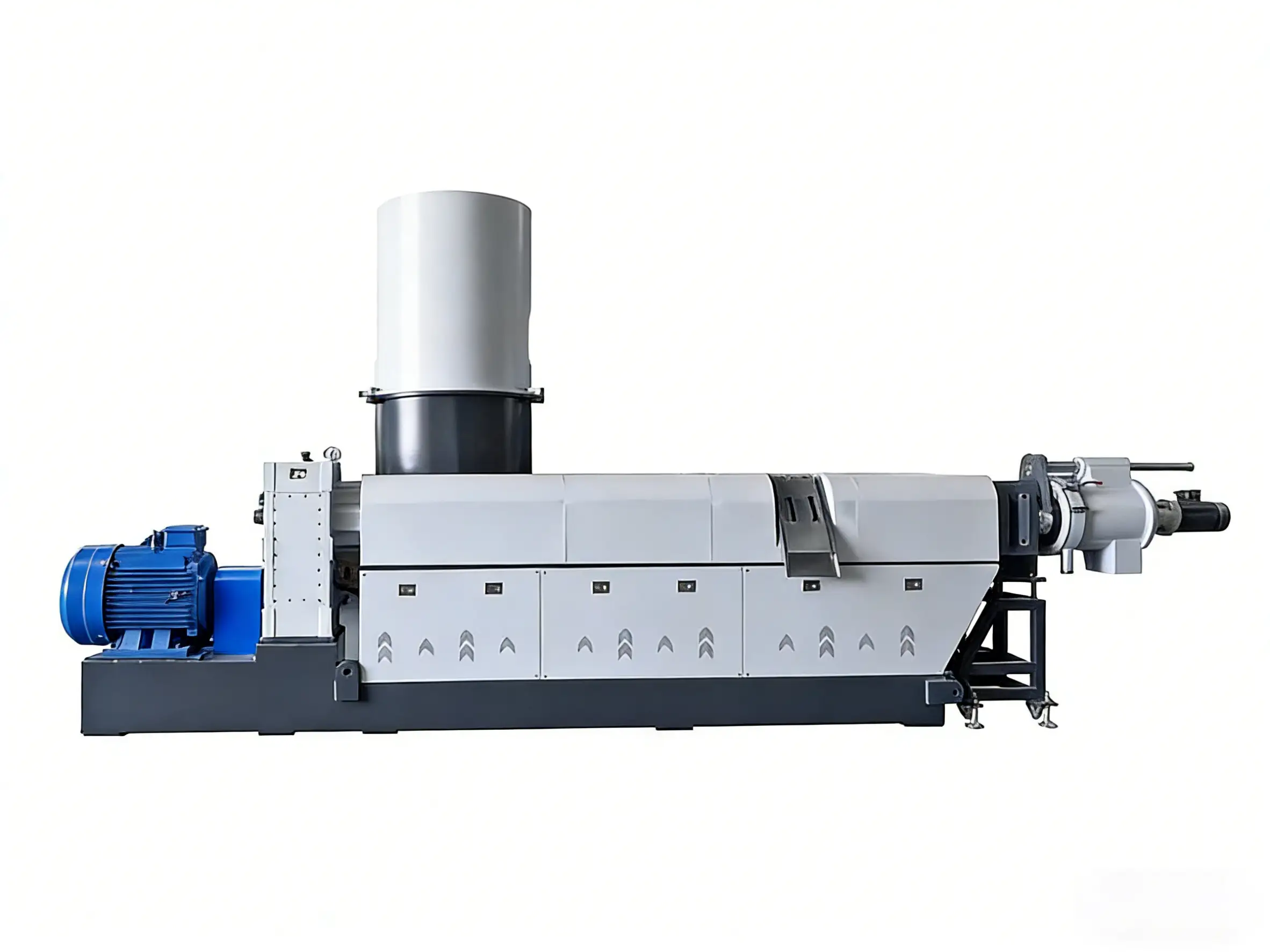

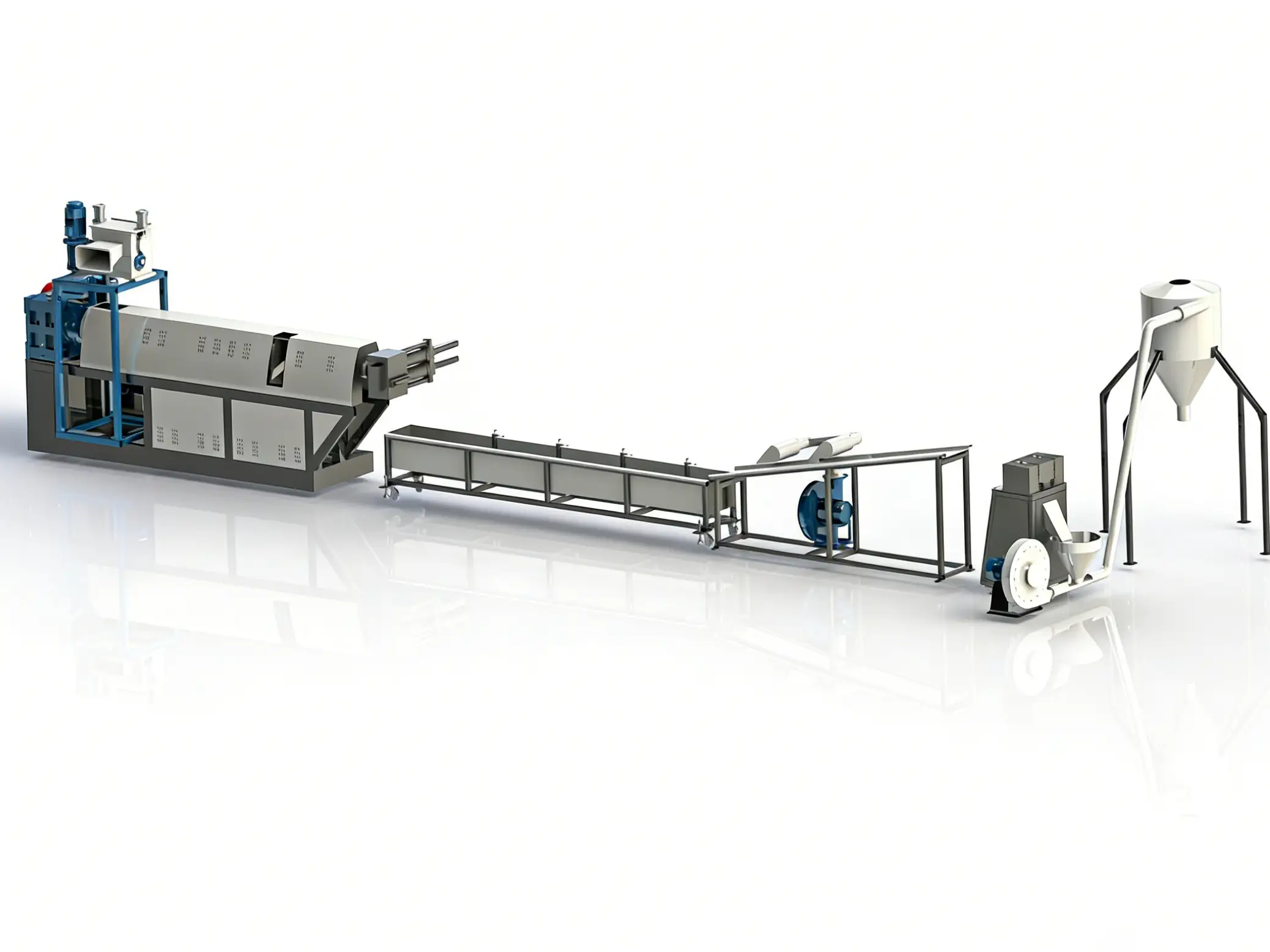

Brief Description of Pelletizing Process

Pelletizing Line Detail Photos

Dosing Feeder

Screw Feeder

Extruder

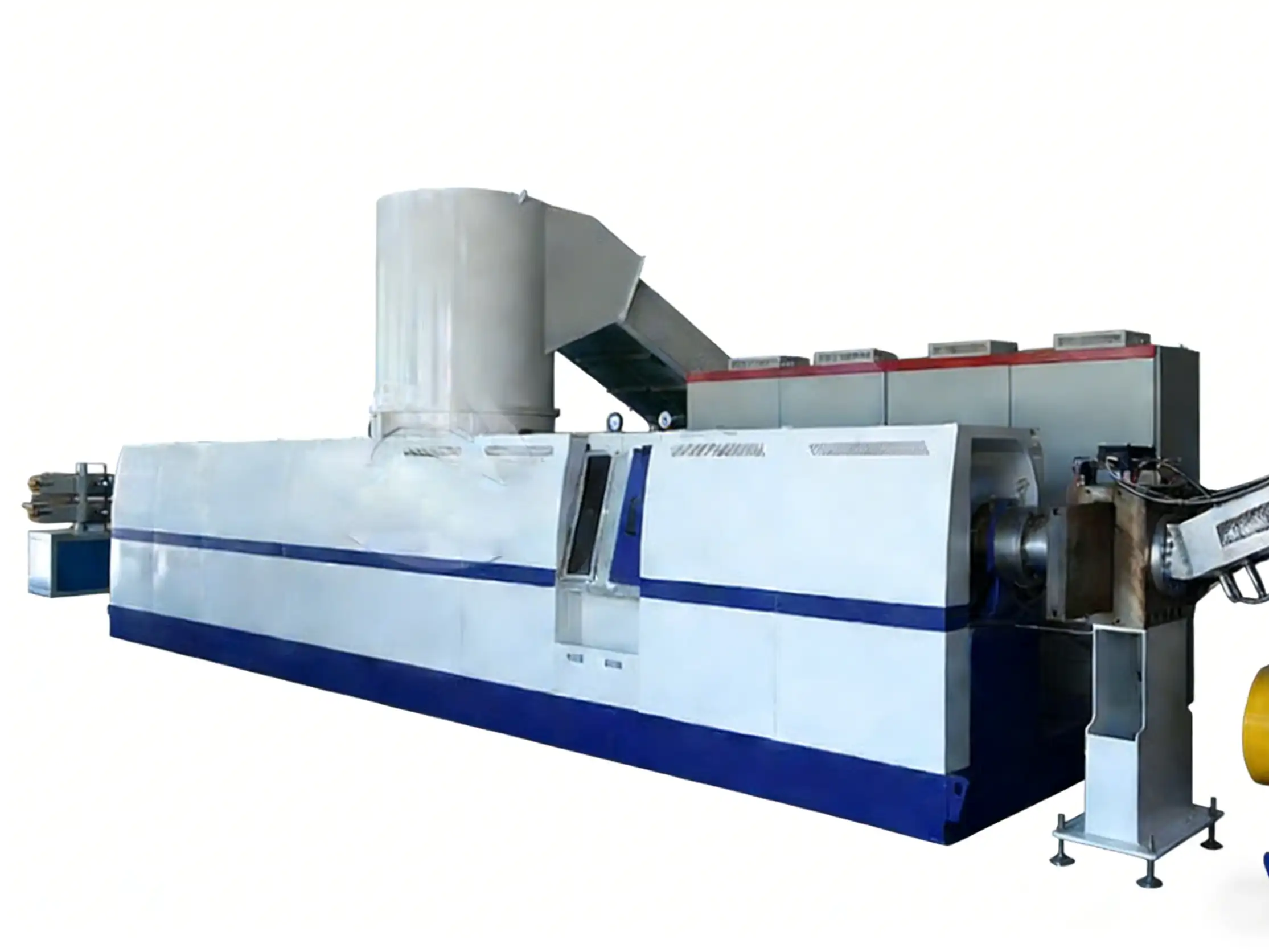

Extruder Submachine

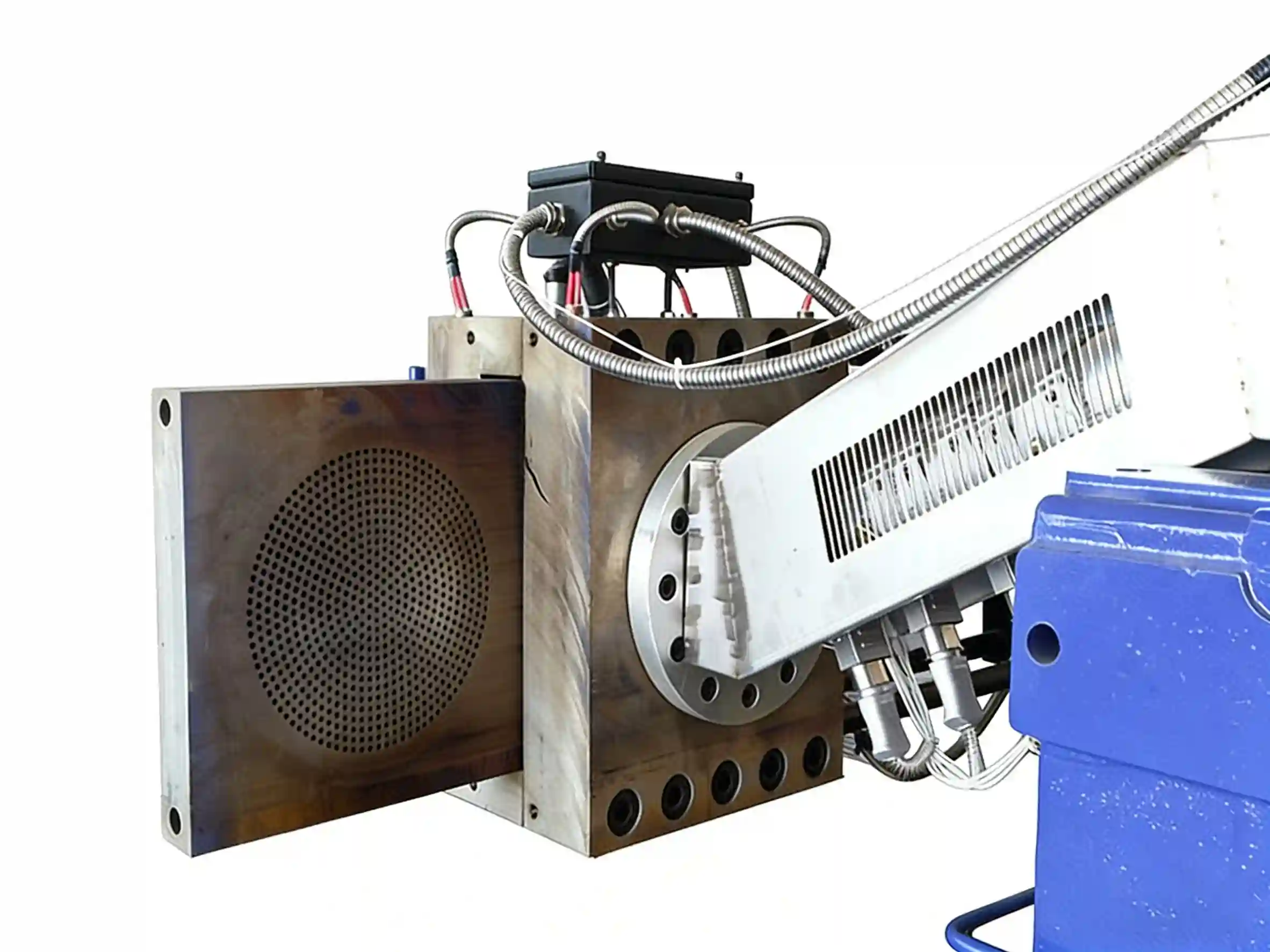

Meshless Drain Filter

Screen Changer Filter

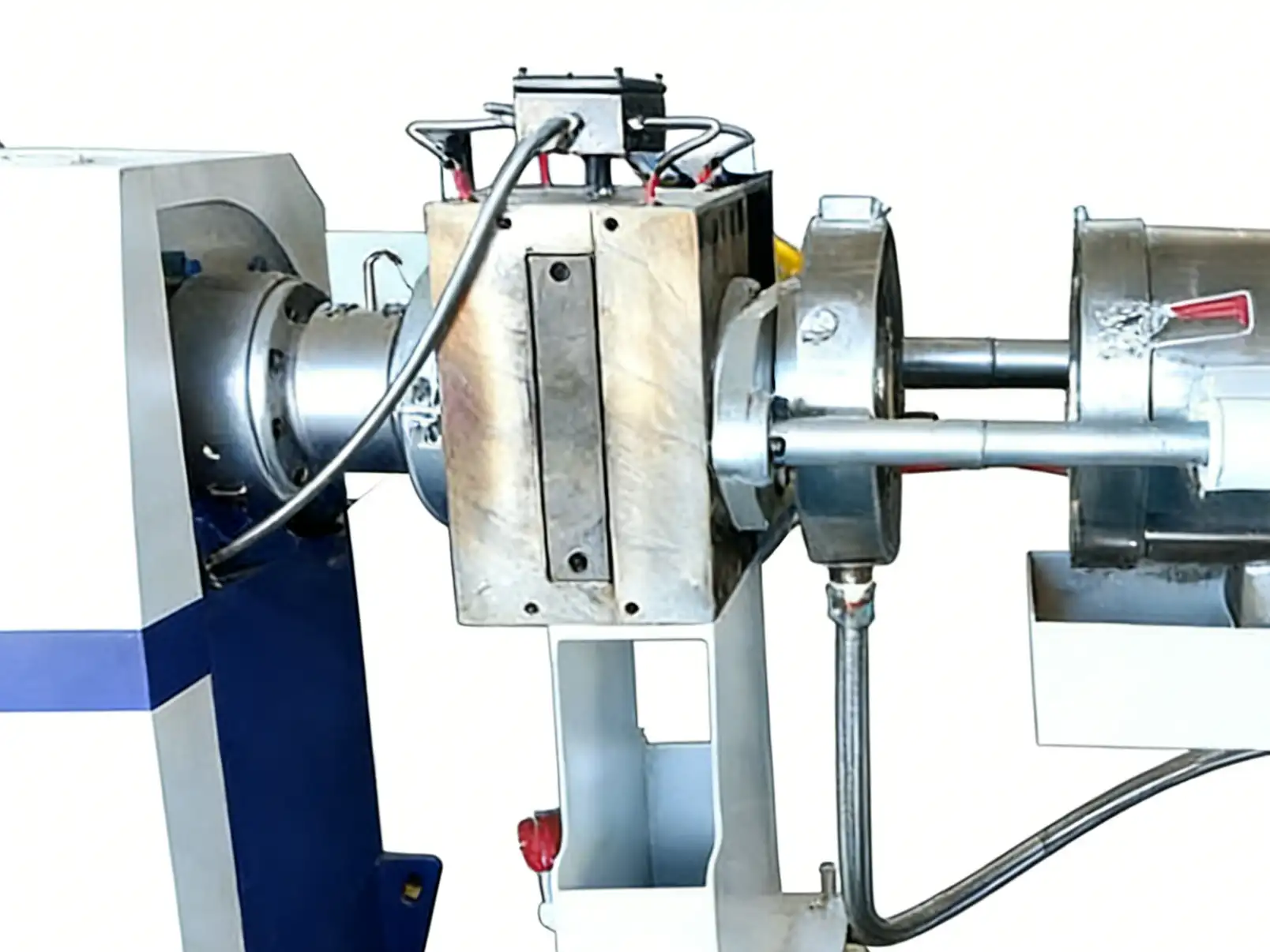

Water Ring Cutter

Vertical Dehydrator

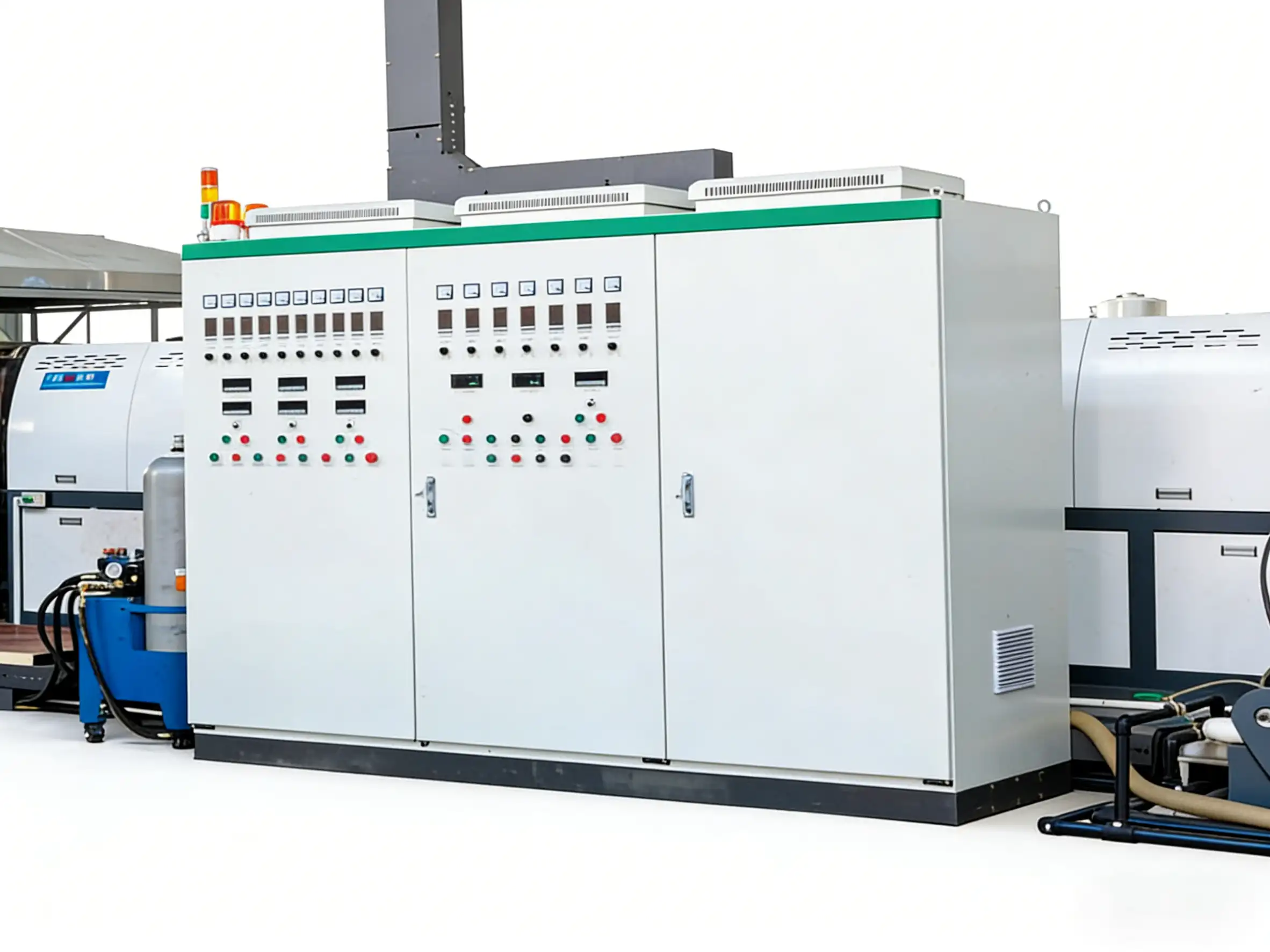

Control Cabinet

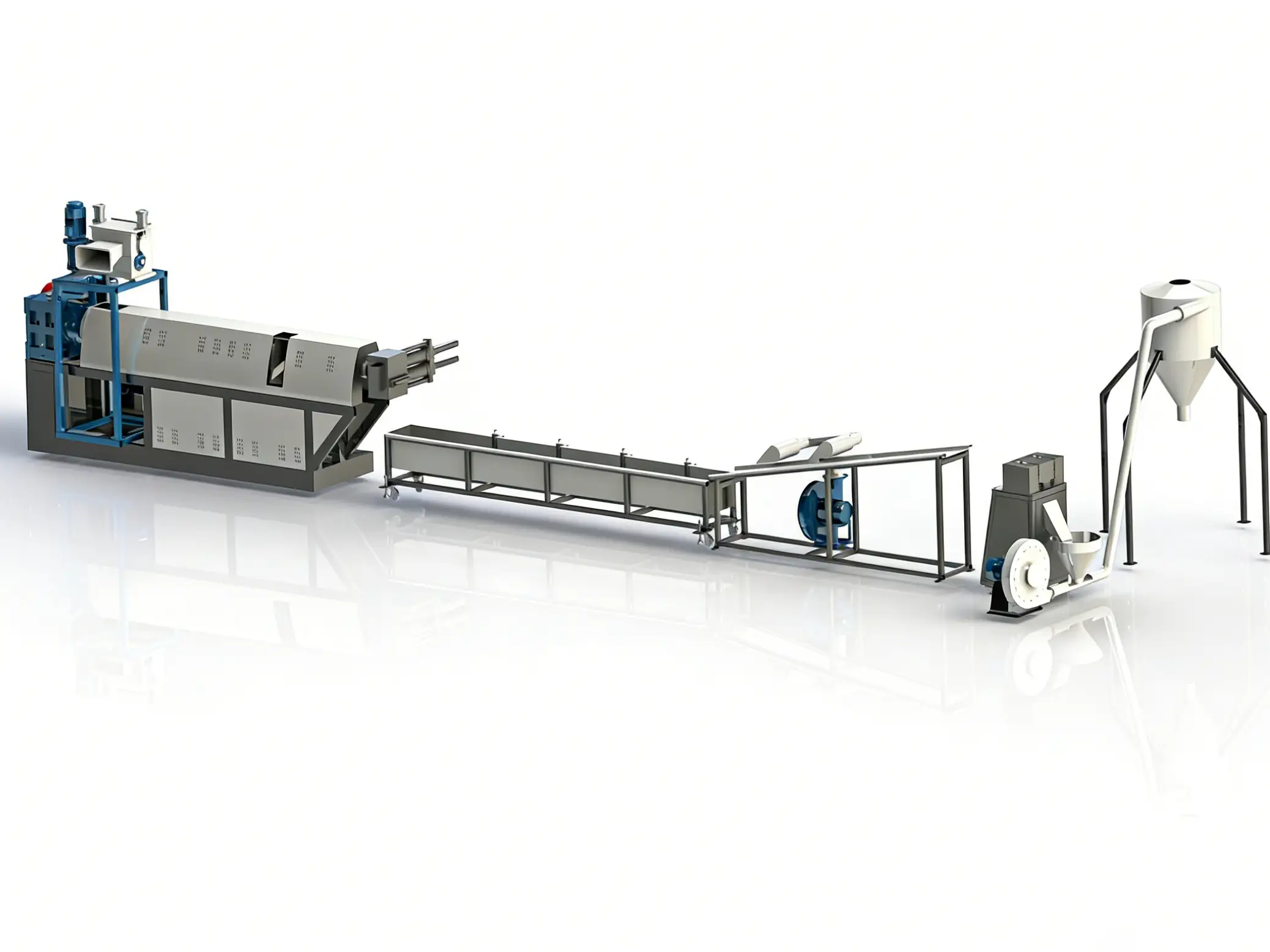

Complete Double-Stage Pelletizing Line for Mixed Plastics

Watch our double-stage pelletizing line processing challenging mixed plastics. See how we handle PVC, ABS, PS and materials with fillers into stable regranulates.

Request A Free Quote

We'd Like To Work With You. Get a customized solution for your pelletizing project.

15+ Years Experience

Professional plastic recycling solutions

50+ Countries Served

Global installation and support

24–48h Response

Fast engineering support

Get Your Free Quote

Tell us your material and capacity — our engineers will recommend the right configuration.