Heavy-duty size reduction solutions designed for stable feeding and downstream recycling processes.

Best for:

Output control: Adjustable screen size for consistent particle size

Note: Ideal for continuous operation in demanding environments

Best for:

Output control: Precise screen and rotor configuration for uniform output

Note: Versatile for mixed material streams

Best for:

Output control: Optimized cutting geometry for long materials

Note: Designed for efficient processing of extended plastic forms

Various plastic materials suitable for shredding and size reduction

Tell us your material and capacity — our engineers will recommend the right solution.

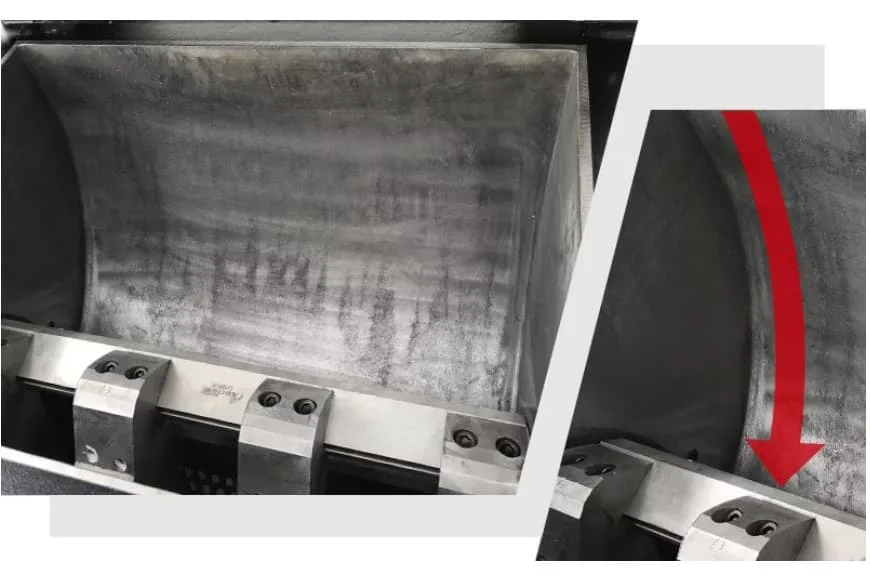

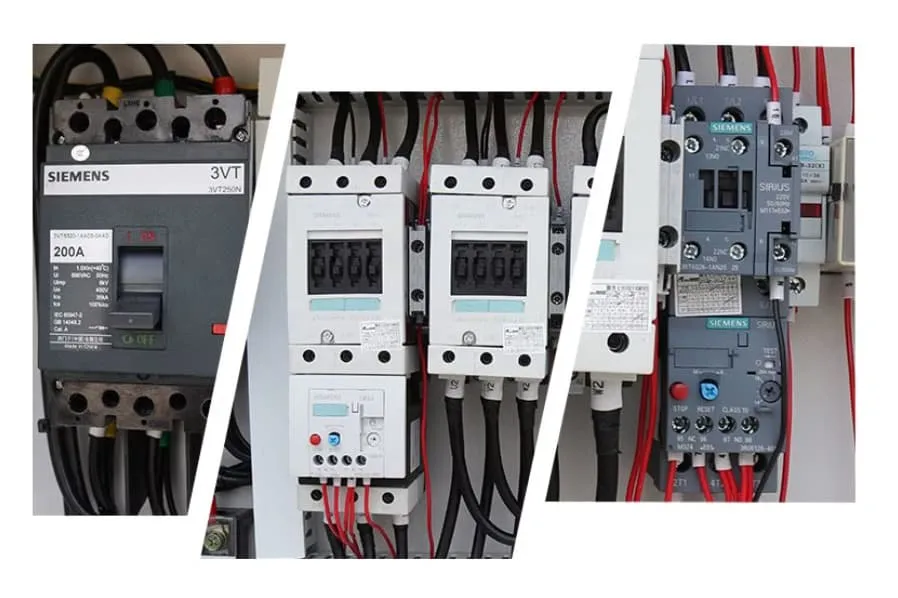

Engineered for continuous operation under high load conditions with minimal maintenance requirements.

Customizable cutting blades and screens available in various materials to handle challenging waste streams.

Safety interlocks and ergonomic design ensure operator safety and simplified maintenance procedures.

Tell us your material, capacity and project needs.

Your inquiry has been sent successfully.

Our engineering team will contact you shortly.